Guar Gum is derived from the ground endosperm of the guar plant, Cyanmopsis Tetragonolobus belonging to the family Leguminosae. The guar plant is mainly grown in India and Pakistan from the month of July to December. Availability and pricing are depending very much on the quality of the monsoon during this period, major Guar is grown in India (Rajasthan, Harayana, Punjab and Gujarat)

Guar is obtained from the ground endosperms of Cyamopsis Tetragonolobus (Linne) Taub. (Fam Leguminosae). It consists chiefly of a high molecular weight Hydrocolloidal polysaccharide, composed of Galactan and Mannan units combined through Glycosidie linkages, which may be described chemically as a Galactomannan

Guar or cluster bean is believed to have originated in Africa but is been grown throughout southern Asia since ancient times as a vegetable and fodder crop. Guar has been cultivated in India and Pakistan for ages for use of its tender pods as fresh vegetables and other parts of the plants to be used as cattle feed. The plant is extremely drought-resistant, being able to absorb efficiently all ground water. It grows therefore easily in those semi-arid regions where less hardy crops perish. The major world supplier of guar seed are India, Pakistan and United States.

Guar is a crop of semi arid–sub tropical areas spread over the North and North West of India and East and South East of Pakistan. India accounts 80% of the world guar production. Guar is grown in arid zones of Rajasthan (74.15%) and other some parts of Gujarat, Harayana, Punjab, Madhya Pradesh. Jodhpur City in the North Western state of Rajasthan in India is the most important processing centre of Guar Gum and contributes approximately 40% of the world's Guar Gum supply. .

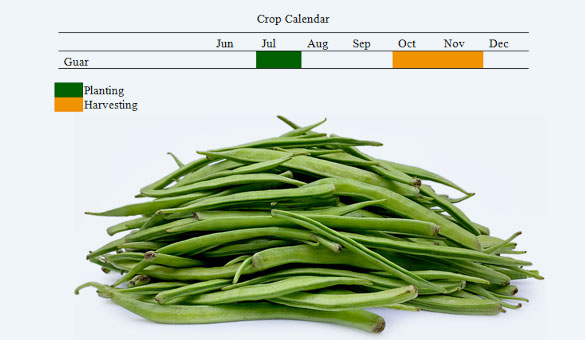

In India, the sowing season for guar seed is end of July and it is harvested during November. It is usually 90 days crop.

Guar is a rain fed monsoon crop, which requires 8-15 inch of rain in 3-4 spell. For effective guar cultivation, the crop needs two rainfalls before sowing, one rainfall when the crop buds out and another when the crop comes up well and blossoming starts. Then it requires plenty of sunshine and dry weather to come up really well. During harvesting period it again needs good sunshine in order to dry up and become usable for industries.

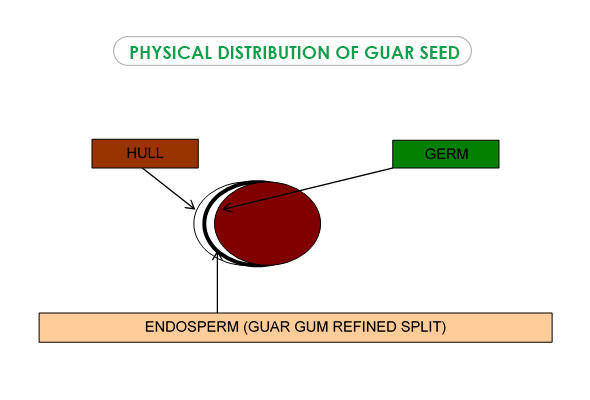

Guar gum is a white to yellowish white powder. It is nearly odorless. It is extracted from the seed. Guar Gum Refined Splits (Endosperm) is the sole raw material for processing Guar Gum Powder for Pharmaceutical and Food Grade material. Guar gum is an emulsifier, thickener, and stabilizer approved for use in a wide range of foods, cosmetics, and pharmaceuticals. It is sold as a white to yellowish odorless powder, which is available in different viscosities and different Granulometries depending on the desired viscosity. Its thickness is a function of temperature, time, and concentration.

One advantageous property of guar gum is that it thickens without the application of heat. Guar Gum has the following properties, which make it useful in variety of applications.

Guar, one of the most versatile seed, rich in multiple properties and uses.

Guar Seed is the basic Raw Material. The Guar Seed is processed and the following are the results:

Guar Gum Split is manufactured from Guar seeds and refined to different purity levels as per buyers' requirements. This is the basic raw material for Guar Gum Powder production.

| Specifications of Guar Gum Splits | |

|---|---|

| Gum Content | 80-85% |

| Dehusked Splits | 90% Minimum |

| Protein | 5% Maximum |

| Ash | 1.0% Maximum |

| Moisture | 10% Maximum |

| AIR | 2.5% Maximum |

| Product Name | GF50 | GF45 | GF55 | GF70 |

| VISCOSITY - 1% (CPS) | 5200 | 4500 | 5500 | 6800 |

| GRANULATION | -200 | -200 | -200 | -200 |

| 90% Min | 90% Min | 90% Min | 90% Min | |

| DISPERSI-BILITY | Fair | Fair | Fair | Fair |

| HYDRATION RATE | Fair | Fair | Very fast | Very fast |

| GELATION | Non Gelling | Non Gelling | Non Gelling | Non Gelling |

| SUSPENSION POWER | None | None | None | None |

| EMULSION STABILITY | None | None | None | None |

| NATURAL | YES | YES | YES | YES |

| PLATE COUNT | 5000 Max | 5000 Max | 5000 Max | 5000 Max |

| MOLD & YEAST COUNT | 500 Max | 500 Max | 500 Max | 500 Max |

| COLIFORM | NEG | NEG | NEG | NEG |

| E. COLI | NEG | NEG | NEG | NEG |

| SALMONELLA/25gm | NEG | NEG | NEG | NEG |

| STAPHY-LOCOCCUS | NEG | NEG | NEG | NEG |

| PSEUDOMONAS | NEG | NEG | NEG | NEG |

| GF-Drilling Grade Fast hydrating as per customer's requirements Diesel slurriable | |

|---|---|

| PARTICLE SIZE | VISCOSITY RANGE |

| 200 Mesh 99% | 3 Min: 34-50 CPS @ 0.48% Sol. (2% Kcl) |