We at GREENFIELDS DERIVATIVES PVT LTD. are renowned and trusted for its high-quality products. Everyone right from Management to Production & QC personnel are committed to consistently deliver high-quality products that meet or exceed our customer’s specifications.

Food ingredients must be of the highest microbiological purity and it must also be uniform in its physical and chemical characteristics from delivery to delivery. For this reason, the maintenance of consistent high quality production is of paramount importance.

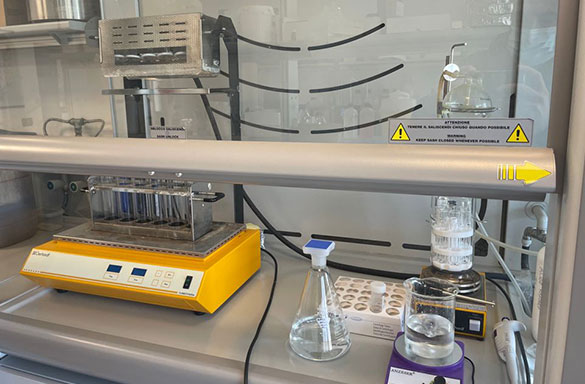

Strict quality control procedures in the form of rigorous laboratory tests are applied systematically at every stage of production from the receipt of raw material to the finished products.

The scientific testing of random samples is being carried out at every intermediate stage of processing. Only after getting approval from Quality Assurance department the intermediate products are used for further processing and final packaging. The stringent care and hygienic conditions that are maintained throughout the processing period, and the fumigation (as per direction pest control of India) conducted before packing the material cannot be contaminated.

Most of our products have raw materials which are natural in origin and which are processed in ambient conditions. In order to achieve consistent quality round the year, we have instituted a simple, rigorous and effective QC system which basically consists of testing at 3 stages as given below